Construction of the Chabanel mechanical ventilation station

Project summary

The rectifier station houses a mechanical ventilation station (MVS). This MVS has reached the end of its useful life and needs to be replaced with a new dedicated building, the Chabanel MVS. The new equipment is necessary for us to meet metro ventilation standards.

The existing rectifier station will also be updated with a refurbished building envelope. Once completed, the exterior will be more visually appealing.

Duration of the work: October 11, 2022 to spring 2026

Description of the work: Expansion of existing rectifier station to integrate a new mechanical ventilation station

Impact on local residents

Night work

During the night of Monday, April 14 to Tuesday, April 15, night work will take place between 10 p.m and 7 a.m on the Chabanel mechanical ventilation station worksite.

| Action | Date | Update |

|---|---|---|

| Deployment | Octobrer 2022 | Complete |

| Building demolition | October 2022 to December 2022 | Complete |

| Excavation | January 2023 to spring 2024 Shaft: completed in April 2024 Tunnel: completion scheduled for spring 2024 | Complete |

| Concrete work | Started in May 2024, until the end of summer 2025 | Ongoing |

| Finishing, testing and commissioning | Winter 2026 | Upcoming |

| End of project | Winter 2026 |

Exavation is now complete.

This step of the work could generate vibrations and noise around the area, but the following mitigation measures will be in place:

- An anti-noise wall was previously installed on the west side of the worksite (on the alley side) to reduce the noise level.

- Noise partitions will be installed at various points around the worksite.

- Sound levels will be measured to ensure that they do not exceed permitted thresholds.

- Seismographs have been installed in strategic locations to monitor vibrations and prevent any damage to infrastructure.

- The work will be mainly conducted Monday to Friday, between 7 a.m. and 7 p.m., in accordance with municipal by-laws.

To reduce noise, we made the following improvements to the worksite:

- The noise wall on the alleyway side has been enhanced. It is covered in insulating wool and has been extended to at least 3.8 metres tall on the back and side perimeters and up to 6 metres tall in certain critical areas.

- A platform has been installed within the worksite, above the excavation area. With insulating wool on its floor, it will help reduce noise by acting as a partial ceiling over the excavation area. (The photo shows the platform being built.)

- We continue to measure noise levels at the worksite on a regular basis and evaluate other noise reduction solutions that could be implemented to reduce the impact on your life.

- The noise wall along the alleyway will be raised to better protect that area. A 1.8-metre (6-foot) section will be positioned upward to direct noise up and away from homes.

- Acoustic insulation (650 square metres in total) will be installed in the shaft to limit noise reverberation during the excavation.

- In addition to these two new measures, a temporary roof was recently suspended over the jackhammer to contain the noise produced by it.

This committee allows residents living near the site to meet periodically with the people in charge of the project to receive up-to-date information and discuss their concerns during the work.

Representatives of the STM, the Ahuntsic-Cartierville borough and local residents are present at these committee meeting.

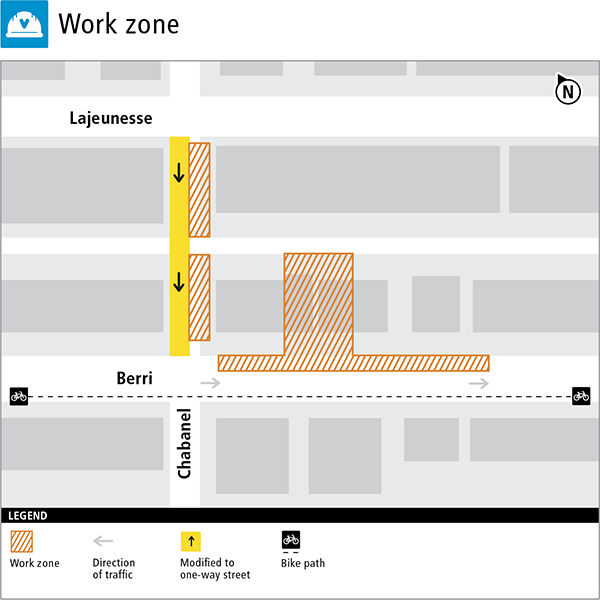

Berri Street:

There is a worksite on Berri near Chabanel. One southbound lane will remain open at all times in this area.

The bike path will remain in its current location, along the west curb of Berri.

Some parking spaces on Berri are blocked off near the worksite.

Chabanel Street:

Two storage areas needed for the worksite are located on the south side of Chabanel Street between Lajeunesse and Berri.

During the work, Chabanel will be a westbound one-way street between Lajeunesse and Berri, and curbside parking on Chabanel will be blocked off in this area.

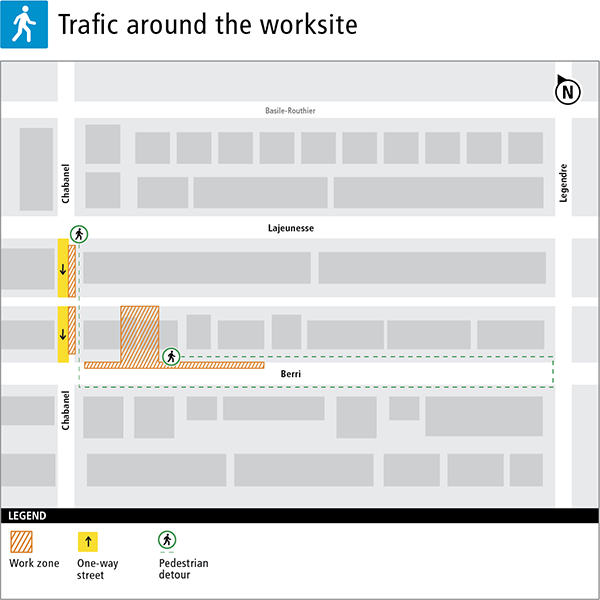

At the Berri and Chabanel intersection, a portion of the northeast sidewalk will be blocked during the work. Pedestrians can use the west sidewalk in this area.

Please note that the work will at no time block pedestrian access to homes.

- Any construction work likely to generate noise will be scheduled during the hours allowed by municipal regulations, 7 a.m. to 7 p.m., Monday to Friday.

- While the majority of the work will take place Monday through Friday, it may be necessary for it to continue on Saturdays and possibly, but more rarely, on Sundays in order to meet the project deadline. Should this happen, any extensions will be announced on this page, and an electronic newsletter will be sent out to subscribers.

Excavation

- Excavation work will produce vibrations that may be felt by residents living next to the worksite. The contractor hired an independent consulting firm to survey all buildings (photographs) around the worksite. The inspections will serve to document the condition of buildings before and after construction. In the unlikely event that any damage is reported, an expert opinion could help determine whether the damage is the result of the vibrations produced by the project. Property owners concerned by the inspections have received a communication from us to this effect.

Dust

- Anti-dust sheets are installed on the worksite partitions, and trucks will be cleaned before leaving the worksite.

Noise

- Noise management for the project will be overseen by experts, and surveys will be conducted at various phases of the work to assess the noise level of the site.

- To limit the impact on residents, the STM included an additional specification in the agreement with the contractor regarding noise levels from the Chabanel MVS worksite. As a result, the contractor must take significant measures to control the noise generated by the worksite. The STM will also be monitoring noise levels.

- When possible, electric cranes and compressors will be used to reduce noise and CO₂ emissions.

- Construction noise will be minimized by partitions of varying heights made of wood and filled with acoustic insulation. These noise walls will be placed strategically around the edge of the worksite, based on noise simulations produced by an expert company. The walls will reduce the noise caused by the worksite. Adjustments and improvements can also be made throughout the work to minimize impacts during construction.

Significant measures have been taken to ensure the safety of both nearby residents and workers:

- The crane is an electric model, which creates less noise than the diesel-powered mobile cranes and produces no exhaust gas.

- The crane will not be used when weather conditions are unfavourable.

- When not in use, the crane will be left in “weathervane mode,” allowing it to pivot freely on its axis in strong winds. If you see the crane turning while the worksite is closed, this is normal!

- The crane will be equipped with a “zoning system.” This electronic system allows the crane to be programmed with boundaries that stop it from lifting or moving a load into preset zones. The boundaries will be applied to the entire perimeter of the worksite to ensure that no lifting takes place over nearby homes or public areas. If lifting in a public area is necessary, a safety perimeter will be set up with a flagger present to redirect the flow of pedestrians and vehicles.

FAQ

The worksite is a considerable size. We have to dig into the rock bed to create a vertical shaft to a depth of 23 metres. We will then excavate a 18-metre tunnel, removing a total of 5,790 cubic metres of bedrock from the site. After that, we will install a waterproofing membrane over the tunnel to protect it from water infiltrations. Next comes the concrete, which will form the tunnel and underground building. Finally, fans and their accompanying electrical equipment will be installed. All of these steps vary in terms of duration and impact, such as noise and dust.

Trucks will access the worksite via Berri Street and will be parked inside the worksite fences. The number of trucks will vary depending on the type of work being done. At the height of the excavation work, there may be up to roughly 15 trucks per day. A flagger will be present when trucks are driving on Berri to ensure cyclist and pedestrian safety.

Given the excavation method used, and depending on your home’s soil composition, you may feel vibrations at certain times. An expert was hired by the contractor to inspect potentially affected buildings before the start of the work. The buildings could also be reassessed after the work is complete. If this applies to your building, you will have already received a letter.

The Chabanel MVS project construction contractor is responsible for removing snow from the worksite itself and from the sidewalk on the east side of Berri Street in front of the worksite. The borough being reponsible for snow removal for the sidewalks and streets, we have contacted them to ensure that our worksite does not interfere with these activities.

We have also coordinated with the private snow removal company hired by residents for the alleyway to ensure that snow removal can be done as usual during the work.

The alleyway will remain accessible to residents and cars during the work. However, due to the nature of the work and the location of the site, occasional obstructions will be necessary in the alleyway next to the worksite when the project begins. The alleyway traffic could be temporarily restricted or blocked for certain work - for example, asphalt removal, pile installation and anti-noise wall construction. These temporary traffic restrictions will be in place during the worksite’s active hours only and are necessary to ensure the safety of all while there are cranes in operation.

Traffic in the alleyway will be restricted around the worksite until Hydro-Québec removes a utility pole in the summer of 2023, but enough space will be available for vehicles to drive through until the work is completed.

Since the worksite is located on a stretch of Berri Street, a procedure has been established with the City to ensure weekly garbage and recycling collection services for nearby residences. A notice has been mailed out to these residences.

Waste collection and collection of recyclable materials:

- All waste or recyclable material must be in bags, with the exception of bulky items (furniture or household appliances). We ask that you use garbage or recycling bags as appropriate. These bags must then be deposited in the suitable bins.

- The contractor is responsible for waste collection from residences near the worksite. He will return your bin to the front of your residence after collection. Don't forget to identify your bin with your address.

- On the morning of the collection, we kindly ask you to deposit your bins in front of your residence before 7:00 AM to allow us time to pick them up before the city’s collection.

Collection of food residues:

- Food waste bins can be placed on the sidewalk as usual on the morning of collection. However, we ask you to bring your bins to the sidewalk before 7:00 AM to allow us sufficient time to manage them before the city’s collection;

- Please identify your brown food waste bins with your door number to facilitate its return to you.

If you live near the worksite and are planning a move, delivery or home renovation, we encourage you to contact us as soon as possible to arrange access to your building.

Fill out the form and please provide the following information:

- Your name

- The expected date of your move, delivery or home renovation

- Whether it is a move, delivery or home renovation

- Your address

- Your phone number

Once the work is complete, the mechanical ventilation station will comply with all City of Montréal noise by-laws. Huge noise suppressors will mitigate the noise from the fans, installed below ground level, to ensure quiet for residents living nearby. The noise will not exceed 50 decibels, a level comparable to that of a household dishwasher.

We care about the quality of life of residents living close to our facilities. Rest assured that we will take all measures necessary to keep the work’s impact on your activities to a minimum.

Learn more about the project

A mechanical ventilation station is an infrastructure located between two métro stations that is equipped with two fans designed to extract hot air from the métro network through inlets fitted with air vents. Ventilation stations built for the original métro network extract around 60,000 cubic feet of air per minute, while the new ventilation systems extract around 240,000 cubic feet per minute. Huge noise suppressors mitigate the noise from these fans to ensure quiet for residents living close to a ventilation station.

Mechanical ventilation stations serve three essential purposes:

Comfort ventilation

Regulates the ambient temperature and supplies fresh air for transit users by exchanging air from the outside with air inside the métro network.

Night-time ventilation

Ensures a supply of fresh air for night workers carrying out routine maintenance.

Emergency ventilation

In the event of an incident, controls smoke and provides a safe evacuation route for passengers via the nearest métro station and ensures unobstructed access for emergency first responders.

1. Preparation of worksite

- Fencing off the work area

- Installing work equipment

Approximate timeframe: 2 months

2. Excavation at ground level

Approximate timeframe: 5 months

3. Excavation in the rock bed

Approximate timeframe: 12 to 14 months

4. Installation of a membrane to ensure water-tightness of all infrastructures

Approximate timeframe: 2 months

5. Concrete work for ventilation station

- Concrete work for all infrastructures

Approximate timeframe: 9 months

6. Installation of mechanical and electrical equipment, as well as architectural finishes and exterior design

- Delivery of equipment to worksite

- Installation of equipment

- Performance testing on mechanical equipment

- Construction of ventilation station’s external structure

Approximate timeframe: 4 months

Let's chat

A virtual information session was held on September 13, 2022

Contenu de l'onglet 5

Do you live, run a business or work in the area?

Stay informed of the project’s progress and other events by signing up for the electronic newsletter.

The project in images

Models of the existing building (left), which will be updated and renovated, and of the

projected expansion (right), including the new Chabanel mechanical ventilation station.

The architectural designs shown here are subject to change.

This work is made possible through funding from the Ministère des Transports du Québec.