Frequently asked questions

Controlled microblasting

Controlled microblasting is already used on several major STM worksites, depending on the type of rock to be excavated.

It’s safe, much faster and more effective than mechanical methods, and reduces neighbourhood disturbances, making it an excellent solution for densely built environments.

Watch this short video to learn more about controlled microblasting in urban environments

Video in French, English subtitles available

Given the composition of the rock to be excavated along the extended métro line, controlled microblasting is much faster and more effective than mechanical methods. The alternative to microblasting would be to use hydraulic jackhammers to break up the rock, which would be noisier and take much longer.

Controlled microblasting limits neighbourhood disturbances when excavation work is needed.

Controlled microblasting is a safe blasting technique that uses low-volume, individually triggered blasts. We use reduced charges to limit vibrations, noise and possible rock fragment projectiles, or fly-rock.

Each low-volume blast lasts 0.3 to 0.5 seconds. During this short period, a series of small, calculated explosive charges are triggered.

Strict vibration standards must be met for all above-ground buildings, as well as underground infrastructure such as sewers.

Each type of structure is classified according to specific criteria that determine the maximum vibration threshold to be met. This threshold has a very high safety margin compared to the minimum vibrations that would potentially cause cosmetic damage to the structure.

For each blast, qualified engineers calculate the estimated vibrations to ensure that vibration thresholds are met.

During the blast, seismographs installed near the buildings closest to the blast are used to measure the vibrations.

This data is then transmitted to the engineers so that they can calibrate and refine their calculation model. The data collected allows them to ensure the blast was compliant, make any necessary adjustments, and achieve even greater precision in planning the next blast.

All buildings located within a 75 m radius of excavation faces will be inspected by an independent, specialized firm. This procedure is a common precaution aimed at protecting building owners in the very unlikely event their building suffers any damage. The data collected on the condition of buildings also allows us to better plan blasts, based on the environment.

To ensure full control of each microblast, only the latest-generation cartridge explosives will be used. No bulk explosives are authorized. The aim is to make sure that for each microdetonation, the blasting team has full control of the explosive charge at all times. It also allows the team to avoid any loss of product in the rock fissures during loading.

To trigger the cartridge explosives, the blasting team uses programmable electronic detonators. These high-precision products allow for optimal vibration control and allow the team to check the entire firing circuit prior to blasting.

It’s also important to note that no explosives are stored at the worksite. Any excess charges are safely transported off site and properly stored.

Each blast is completely covered with blasting mats made of recycled tires.

A double or even triple thickness of blasting mats is placed directly on top of the blast. The mats are so heavy that hydraulic shovels have to be used to put them in place.

The blasting mats are removed immediately following the blast so that the excavation team can start excavating the blasted rock.

In addition to controlling fly-rock, the blasting mats dampen the noise from the blast and control dust.

To minimize the risk of emissions, we only use explosives that generate the least possible amount of blasting fumes. There are also very rigorous provincial standards that must be met for each blast. That includes giving each resident within a 100‑m radius of the blasting area a carbon monoxide detector to install in their basement.

To find out more about carbon monoxide emission control, consult the Frequently asked questions of our partner Gestion Monox Inc.

Information session on controlled microblasting

An information session was held on April 3, 2025 to learn more about this excavation method and to give the chance to ask our experts all the questions.

Consult the presentation (in French only)

Consult the the recording of the information session (in French only)

Project planning

At this stage, based on the information that we have and the scenarios that are possible, we should be able to open the Blue line extension in 2031. Due to operational constraints, the five new stations will all have to be opened at the same time.

The STM will act as the principal contractor and project manager. As operator of the Montréal métro for the past 50 years, the STM has expertise and experience that will benefit the project.

Contenu de la section extensible.

These decisions were made by the métro extension project office, made up of the Agence métropolitaine de transport (AMT) and the Ministère des Transports du Québec (MTQ), from 2011 to 2015. Their analyses led to the finalized design plan regarding:

- Route

- Locations of entrance buildings

- Bus terminals

- Park-and-ride lot

They used a method called multidisciplinary analysis (MDA), allowing them to examine the pros, cons and limitations of each option, from the perspective of each of the following disciplines:

- Métro operations

- Public transit and station access

- Urban integration and environment

- Work impact management

- Urban development

- Finance

- Socio-politics

- Constructability

These in-depth analyses brought together the various stakeholders (the MTQ, the AMT, the City of Montréal and its relevant boroughs, and the STM) to finalize the design plan that we have today.

For more information and to see the benefits of the chosen options, see our summary (french only).

In line with our commitment to integrate sustainability best practices, we are seeking Envision verification for this project. The Envision reference framework was developed to cover all the sustainable development aspects of an infrastructure project and each phase of its life cycle (planning, design, construction, operations and maintenance, and end-of-life). It is the top sustainable development tool in North America for major infrastructure projects such as metro and streetcar systems.

Verifying the project will allow us to:

- Consult and involve stakeholders

- Mitigate construction impacts on our community and environment

- Reduce the impacts of materials used (resource consumption and manufacturing emissions)

- Rehabilitate contaminated land

- Reduce operational impacts (residual materials, water and energy savings, noise and vibration reduction, etc.)

- Improve vegetation cover

- Improve the project’s resilience to climate change

To learn more, visit the Institute for Sustainable Infrastructure Website.

In February and March 2020, a public consultation process took place in the form of several information evenings and input sessions. The goal of this community dialogue was to design a project that would integrate seamlessly into the lives of Montrealers.

The Commission leading this process has submitted its report and issued 43 recommendations that will allow us to enrich the project and produce infrastructure that meets the expectations of our customers and citizens. Read the report and the action plan.

Azur trains will run on the entire Blue line as soon as the five new stations are commissioned. We must replace the train control system on the current Blue line to ensure that it matches the new technology that will be used on the extension. This is because MR-73 trains are not compatible with the new equipment.

Additionally, since Azur trains must have nine cars, we will redesign the platforms at Saint-Michel station to ensure that they are long enough to accommodate these trains.

Yes, the new stations will be universally accessible and consequently equipped with elevators.

The five new stations will be designed so that platform-edge doors could be installed in the future. However, this will not be done as part of this project.

Progress updates

To prepare for upcoming excavation work, the STM has tasked an independent firm with inspecting buildings that meet at least one of the following criteria:

- Located within 75 metres of any surface-level excavation work

- Located within 30 metres of the tunnel axis

The inspections will be conducted by ABS and serve to compile an inventory of the structures surrounding the worksites for the Blue line extension. The findings of the inspections will also be used to establish the maximum vibration levels for each site. Although these inspections are a precautionary measure, they are essential in the unlikely event that the work causes any damage.

As a further precaution, any building within 100 metres of a worksite where there will be microblasting will receive a carbon monoxide detector a few weeks before the excavation work starts.

Each building inspection lasts approximately 15 to 30 minutes. Photos are taken of the building interior and exterior. The photos are mostly close-ups of the foundations, walls, ceilings, and floors and serve to document the building’s condition prior to the start of the excavation work.

The pre-construction inspection is a common precautionary measure for major construction sites. It protects you in the unlikely event that your property suffers any damage during work on the Blue line extension.

Yes. This is a first for the Montréal métro network. A tunnel boring machine (TBM) is a piece of equipment that digs and builds underground structures. More specifically, it is a massive rotating drill designed to dig and apply concrete in circular tunnels, galleries and shafts.

The cutterhead grinds away the bedrock. This construction method gets the work done faster, provides longer-lasting results and is better for the environment. The TBM also has the advantage of being less noticeable to residents than traditional excavation methods, such as cutting machines and blasting, since it generates less noise and vibration.

In due time, you will be invited to help us choose a name for the tunnel borer by voting on suggestions from our employees.

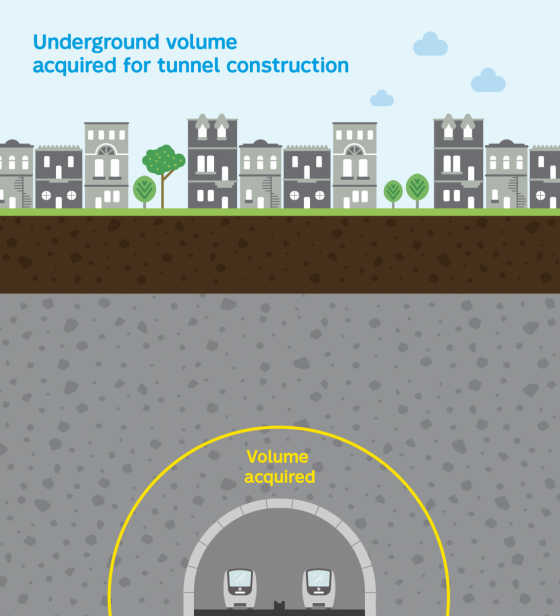

Yes, the law stipulates that the STM must own the underground volume and hold a legal easement when building a tunnel related to a transportation infrastructure project, in this case the BLE.

To do this, we notify the owners and right holders of the lots affected by the work. These owners and right holders are notified by means of a letter delivered by a bailiff.

The tunnel will be located at a depth of between 18 and 40 metres underground. The following infographic provides a better understanding of the volume acquired underground.

The work schedule is tailored to each stage of the project. Our plan is to concentrate activities that generate the most noise during the day, but work may also take place in the evening or at night, seven days a week.

Permitted noise levels are, however, adjusted based on the time of day and the composition of the neighbourhood. At all times, mitigation measures are put in place to reduce noise pollution, and noise levels are also monitored continuously.

The Blue line project construction schedules are planned in accordance with municipal regulations. To accommodate the scope and complexity of the construction sites, the three boroughs concerned by the extension have harmonized their regulations. This enables us to reduce the total duration of construction and help keep the overall project on schedule.

Most of the rock excavated for the new infrastructure will go to the Saint Michel quarry. The city will then be able to reuse it for municipal projects, since the rock will be clean and safe.

Trucks will start taking the rock away in winter 2025. There will be a few dozen trucks a day for about three years. This will happen mostly during the day, but some truckloads may have to go out at night. All rock transportation will be done in compliance with municipal by-laws, and mitigation measures will be taken to limit the impact on the neighbourhood.

.

In the fall of 2024 and 2025, urban forestry work will take place around the Blue line project worksites. Trees that interfere with the construction sites will be protected, replanted, or cut down. Our team of forest engineers, landscape architects, urban planners, and sustainable development experts has carefully planned these interventions to preserve as many trees as possible.

The goal is to replant the trees wherever possible. Soverdi, the not-for-profit organization overseeing the replanting process, will monitor and care for the trees after they are transplanted to ensure their survival. Trees that can’t be replanted due to their size or condition will be recycled into wood chips, firewood or compost depending on the quality of the wood. The health and species of the trees will also help determine which ones need to be cut down, based on whether they are diseased, subject to borer infestations, or invasive, among other factors.

Ultimately, Blue line project sites will be revegetated and several hundred new trees planted, for a stronger, healthier canopy. For every tree replanted or cut down, we will plant more than two in their place.

No, that is not part of the plan.

With the acquisition of the AZUR métro cars and the construction of the Côte-Vertu garage, there will be an increase in the service offer on the Orange line in terms of capacity and frequency. The interval between trains on the Orange line will be two minutes instead of two minutes and 30 seconds during peak periods. Additionally, other major projects should mitigate the impact for Orange line users:

- The Pie-IX BRT, when completed, should provide a connection between the extension of the Blue line and the Green line.

- A connection with the REM is planned for Édouard-Montpetit station to ensure a link with downtown.

Contenu de l'onglet 4

Contenu de l'onglet 5

The blue line extension project follows in the wake of the Déclaration du gouvernement du Québec et de la Ville de Montréal to revitalize Montréal East. Many projects are underway to give a new impetus to this sector. Increased mobility, economic development, and improved living environments are at the heart of this ambitious project. For more information, see Québec.ca/RevitalisationEstMontreal (in French only).